This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

(812) 867-3496

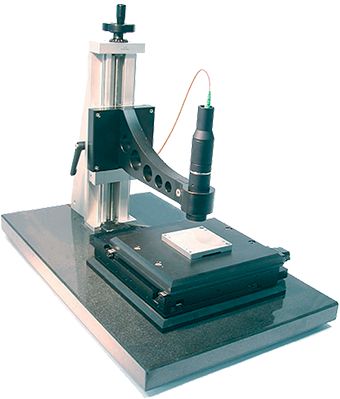

Optotop® – Optical Surface Tester

Surface profile is a key parameter of a product's quality, which affects the product's overall performance. The height values (oftenly refers to the valleys and peaks) of the surface determines many functional features, eg. abrasion resistance, adhesion, etc.

Furthermore, the analysis of wear or abrasion rate after the mechanical tests is also needed to evaluate the quality of surface coatings. Therefore, an accurate measurement and documentation of the surface profile helps to make the right decision for the quality control.

Optotop® is a testing instrument which measures the surface profile in a non-contact fashion. The highly accurate measurement of the 3D topography makes it widely used in R&D for new materials development as well as in the quality control of manufacturing processes.

Parameters which can be measured with Optotop® include:

- Roughness

- 3D Topography/Mapping

- Macro & micro geometries

- Light intensity

- Porosity

- Effective contact area ratio

Advantages

- Easy and comfortable handling

- Rapid data acquisition

- Robust measuring method for various materials, coatings and samples

- Micro roughness index number for linear profile

- Direction-derived roughness index number of areas (texture-orientation analysis)

- Topography as 2-D-line profile, 3-D-display and height profile

Applications

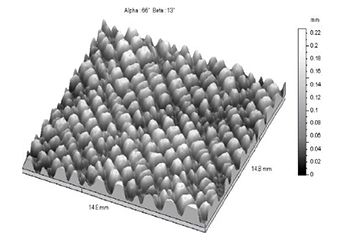

1. Printing Paper

For paper fibers, the distribution of the fibers and microstructure of the paper are the key parameters for the determination of the quality, homogeneity and functionality of a printing paper.

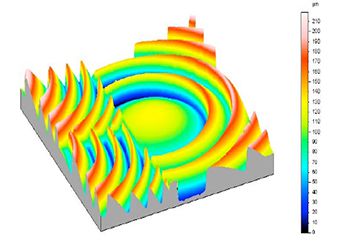

2. Fresnel Lens

3. Structured Leather

Technical Data

| Sensor: | Chromatic Confocal | ||

| Test range Z*: | 300 μm | 1 mm | 2 mm |

| Resolution Z*: | 12 nm | 25 nm | 75 nm |

| Lateral resolution: | 1.55 μm | 2 μm | 4 μm |

| Measuring distance: | 11 mm | 12.7 mm | 16.4 mm |

| Measuring frequency: | 30 Hz, 100 Hz, 300 Hz, 1 kHz | ||

| Standard test range XY: | 60 mm x 60 mm | ||

| Velocity: | 0.1 to 10 mm/s | ||

| Standard table size: | 165 mm x 165 mm or customized | ||

*Further sensors, test ranges and resolutions on request. Data refers to optimised measuring parameters.