(812) 867-3496

UST® – Universal Surface Tester

Adequate measurements are of great importance for a reliable simulation and evaluation of micromechanical properties of materials and surface coatings, such as deformation or haptics. As material and coating behaviour can vary considerably, a series of proper, real-time, quantitative measurements have to be performed with high resolution in the right dimension.

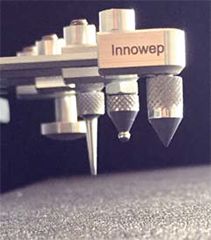

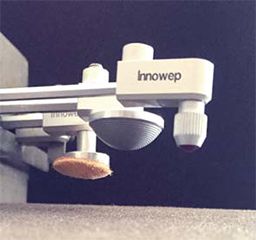

UST®-Universal Surface Tester, is by far the only open multi-modular system that provides a complete mechanical testing solution for the evaluation of bulk materials and surface coatings. Its unique configuration allows for a wide range of tip choices with various materials and sizes ranging from nanometer to centimeter.

Among various kinds of commercial available in-line material property testing instruments, UST® is by far the only tester which close the gap between the traditional macro-mechanical testing machines and nanoscale machines, e.g. nano-indentator and AFMs.

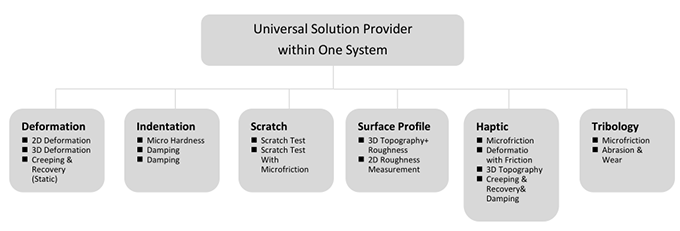

UST®

- One machine for all tests

- Same resolution (60nm)

- No need for correlation

- Local resolution

- Continuous measurement

- Surface structure combined with properties

Other Systems

- One machine for one type measurement

- Different resolution

- Need for further correlation

- No record with local resolution

- Point by point measurement

- No surface structure vs. properties

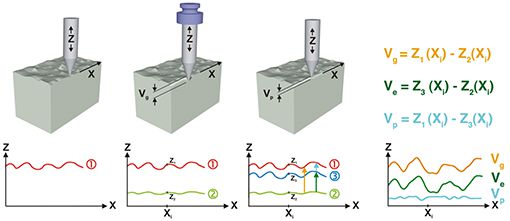

Measurement Principles

The UST® measurement procedure consists of a mechanically scanning by a stylus on the sample surface along a straight line several times. During this patented MISTAN procedure, the stylus is moved on the surface either without load or with a defined load.

- Scan with no load. Surface structure is continuously determined.

- Scan on the same path with additional load to determine total deformation.

- Scan on the same path with no load to determine the elastistic deformation.

- Total deformation = Step 1-Step 2;

- Elastic deformation = Step 3-Step 2;

- Permanent deformation = Step 1-Step 3

Basic Unit

UST®-100 with load range of 1 mN-100 mN

UST®-1000 with load range of 10 mN-1,000 mN for harder surfaces and coatings

Modules

A selection of 10 different modules is available for all types of measurements and applications. Each module includes all necessary hardware, software, suggested tip and necessary tools.

- 3D Deformation

- 3D Topography

- Scratch

- Microfriction (Standard)

- Abrasion and Wear

- Damping

- Viscoelasticity (Creeping & Recovery)

- Universal Hardness

- 2D Roughness

- TAX

Hardware Options

- Exchangable Measurement Head: UST 100 mN and UST 1000 mN

- Microscope: for documentation of the measurement process and results (photo function)

- Videocamera: for documentation of the measurement process and results (video function)

- Optical 3D Topography Module: non-tactile optical measurement of 3D topography

- Vacuum Plate Package: for fixing samples. Vacuum pump is included.

- Mini-Clamping Tool Set: fixing tool for harder samples

- Quick Plates: for easy and quick fixture of samples

Tip Options

Various sizes, geometries, customized tip available upon request